Summary of Contents for Toro 44907

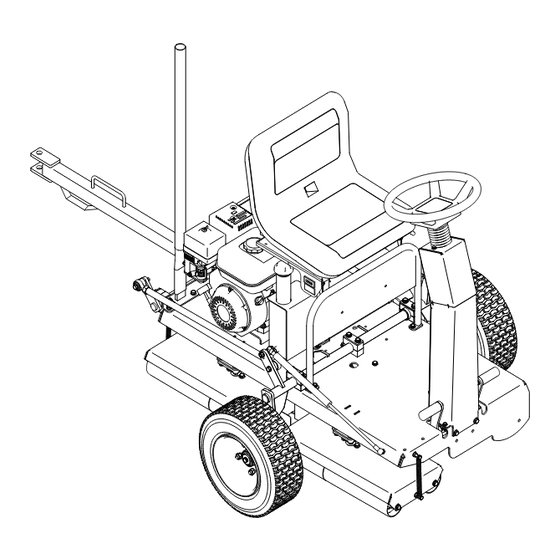

- Page 1 Form No. 3376-137 Rev B GreensPro™ 1200 Greens Roller Model No. 44907—Serial No. 313000001 and Up *3376-137* B Register at www.Toro.com. Original Instructions (EN)

-

Page 2: Introduction

You are responsible for operating the product properly and safely. Figure 2 1. Safety alert symbol You may contact Toro directly at www.Toro.com for product and accessory information, help finding a dealer, or to register your product. This manual uses 2 words to highlight information. -

Page 3: Table Of Contents

Contents Introduction ..............2 Safety ................4 Safe Operating Practices........... 4 Toro Safety............. 5 Sound Power Level ..........6 Sound Pressure Level..........6 Vibration Level ............6 Safety and Instructional Decals ......... 7 Product Overview ............9 Controls ..............9 Engine Controls ..........10... -

Page 4: Safety

Preparation Safety • While operating the machine, always wear substantial footwear, long trousers, hard hat, safety glasses, and ear This machine meets or exceeds CEN standard EN ISO protection. Long hair, loose clothing, or jewelry may get 12100: 2010 specification in effect at the time of production. tangled in moving parts. -

Page 5: Toro Safety

• Do not operate the machine under the influence of alcohol or drugs. The following list contains safety information specific to Toro • Lightning can cause severe injury or death. If lightning products or other safety information that you must know that is seen or thunder is heard in the area, do not operate is not included in the CEN, ISO, or ANSI standard. -

Page 6: Sound Power Level

Keep everyone away. • To ensure safety and accuracy, have an Authorized Toro Distributor check the maximum engine speed with a tachometer. Maximum governed engine speed should be 3200 rpm. -

Page 7: Safety And Instructional Decals

Safety and Instructional Decals Safety decals and instructions are easily visible to the operator and are located near any area of potential danger. Replace any decal that is damaged or lost. 93-6686 111–5646 1. Hydraulic oil 1. Cutting/dismemberment hazard, fan; entanglement hazard, 2. - Page 8 111–5647 1. 1) Release the latch 3. 1) Release the latch securing the transport securing the transport wheels in the lowered wheels in the raised position; 2) Rotate the lift position; 2) Rotate the lift bar to raise the transport bar to lower the transport wheels into the up position.

-

Page 9: Product Overview

Controls Product Overview Note: Refer to your engine operator's manual for complete control information. Steering Wheel The steering wheel (Figure 3) controls the angle of the smoothing rollers, which in turn steer the unit. The amount the wheel can be turned is limited, so the turning circle of the greens roller is relatively large. -

Page 10: Engine Controls

Engine Controls Throttle Lever The throttle lever (Figure 6) controls the speed (rpm) of the On/Off Switch engine. It is located next to the choke control. It sets the engine rpm and therefore can increase and decrease the speed The On/Off switch (Figure 5) allows the operator of the of the machine. -

Page 11: Operation

Filling the Fuel Tank Operation • For best results, use only clean, fresh (less than 30 days Note: Determine the left and right sides of the machine old), unleaded gasoline with an octane rating of 87 or from the normal operating position. higher ((R+M)/2 rating method). -

Page 12: Starting And Stopping The Engine

DANGER In certain conditions, gasoline is extremely flammable and highly explosive. A fire or explosion from gasoline can burn you and others and can damage property. • Fill the fuel tank outdoors, in an open area, when the engine is cold. Wipe up any gasoline that spills. -

Page 13: Transporting The Machine

out, because the rope may break or the recoil B. Slide the bar onto the tab on the left hand side of assembly may be damaged. the lifting arm assembly and secure it with a lynch pin (Figure 9). 6. When the engine has started, push the choke lever to the off position. - Page 14 3. Hold onto the steering wheel, and slowly press either the left or right motion pedal with your corresponding foot, in whichever direction you wish to move. Note: The further you press the pedal, the faster you will travel in that direction. 4.

-

Page 15: Maintenance

Maintenance Recommended Maintenance Schedule(s) Maintenance Service Maintenance Procedure Interval • Check the drive chain tension and adjust it as necessary. After the first 5 hours • Check for any loose nuts, bolts, or fittings and tighten them as required. • Change the engine oil. After the first 20 hours •... - Page 16 WARNING If you are not careful with hazardous substances, they can cause serious personal injury. • Read the labels and instructions for the materials that you use. • Wear the necessary personal protective safety equipment, and use hazardous substances carefully. The following fluids are identified as being hazardous;...

-

Page 17: Daily Maintenance Checklist

Daily Maintenance Checklist Important: Duplicate this page for routine use. Maintenance For the week of: Check Item Mon. Tues. Wed. Thurs. Fri. Sat. Sun. Check that pivot joints operate freely. Check the fuel level. Check the engine oil level. Check the transmission oil level. -

Page 18: Lubrication

Lubrication Lubricating the Linkage Pivot Points Lubricating the Drive-roller Service Interval: Before each use or daily Bearings and the Steering Apply a few drops of SAE 30 engine oil or spray lubricant to Heads all the pivot points after cleaning the machine. Important: After oiling, run the machine off the turf Service Interval: Before each use or daily (lubricate somewhere briefly to disperse any excess lubricant, to... -

Page 19: Engine Maintenance

Engine Maintenance 3. Remove the oil-filler cap/dipstick by rotating it counterclockwise. 4. Wipe the oil-filler cap/dipstick clean and insert it into Engine Oil the filler port. Crankcase Capacity: 0.60 L (0.63 US qt) Note: Do not screw the dipstick into the port. Type: APl service classification SL, SM, SN, or higher 5. -

Page 20: Servicing The Air Cleaner

G025538 Figure 15 Figure 16 1. Wing nut 4. Paper element 6. Turn the oil drain valve 1/4 turn counterclockwise to 2. Air-cleaner cover 5. Foam element start draining the oil (Figure 15). 3. Wing nut 6. Gasket 7. When all the oil is drained, turn the oil drain valve 1/4 turn clockwise to close the valve (Figure 15). -

Page 21: Servicing The Spark Plug

to distribute oil thoroughly. The foam element should be damp with oil. 8. Clean the paper element by tapping the filter element several times on a hard surface to remove the dirt. Note: Never brush dirt off the element or use compressed air to remove dirt;... -

Page 22: Fuel System Maintenance

Fuel System Maintenance Cleaning the Sediment Cup Service Interval: Every 100 hours—Clean the sediment cup. DANGER In certain conditions, gasoline is extremely flammable and highly explosive. A fire or explosion from gasoline can burn you and others and can Figure 19 damage property. -

Page 23: Drive System Maintenance

Drive System C. Install the tank cap. D. Lower the seat and secure the seat plate to the rear Maintenance frame with the bolt and nut previously removed. Checking the Transmission Oil Level Service Interval: Before each use or daily The transmission/tank is filled at the factory with Supersyn 5W-40 synthetic engine oil. -

Page 24: Changing The Transmission Oil

Changing the Transmission Oil Adjusting the Drive Chain Service Interval: After the first 5 hours—Check the drive Service Interval: After the first 20 hours chain tension and adjust it as necessary. Every 800 hours/Every 2 years (whichever comes first) Before each use or daily—Check the drive chain Important: Use only Supersyn 5W-40 synthetic engine tension and adjust it as necessary. -

Page 25: Storage

Storage • To increase the tension, tighten the tensioning nut. • To decrease the tension, loosen the tensioning nut. 1. Remove grass clippings, dirt, and grime from the Note: If there are not enough threads on the external parts of the entire machine, especially the tensioning rod, you can move the locking nut next to rollers and the engine. - Page 26 Notes:...

- Page 27 The Way Toro Uses Information Toro may use your personal information to process warranty claims, to contact you in the event of a product recall and for any other purpose which we tell you about. Toro may share your information with Toro's affiliates, dealers or other business partners in connection with any of these activities. We will not sell your personal information to any other company.

- Page 28 Countries Other than the United States or Canada Customers should contact their Toro Distributor (Dealer) to obtain guarantee policies for your country, province, or state. If for any reason you are dissatisfied with your Distributor's service or have difficulty obtaining guarantee information, contact the Toro importer. If all other remedies fail, you may contact us at Toro Warranty Company.